Product Description

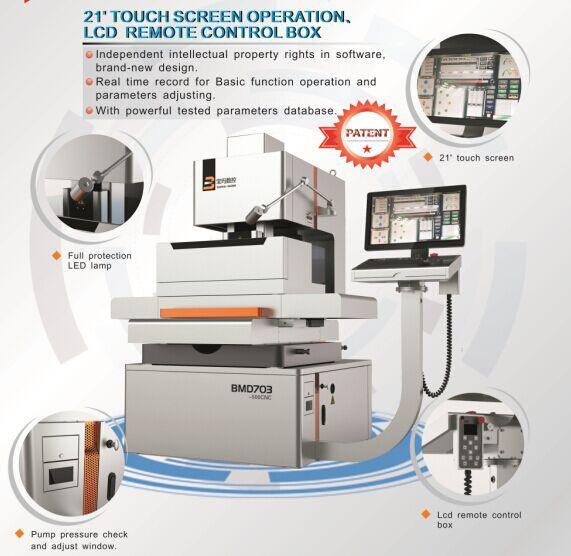

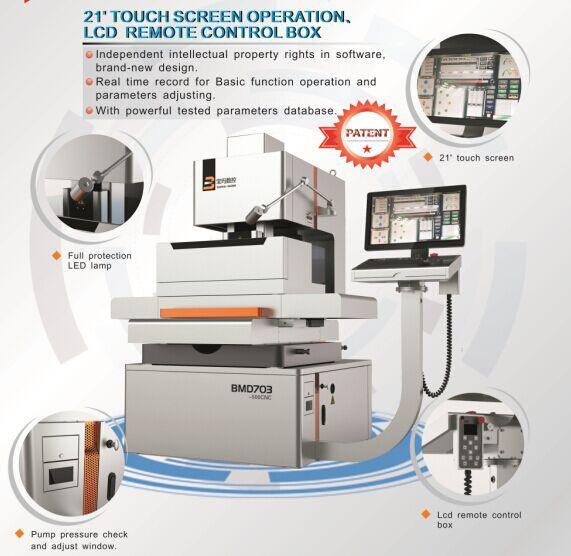

BMD703-500CNC

BMD703-400CNC

INTRODUCTION:

- Control system with BAOMA independent intellectual property, can prepare a new program during drilling

- LAN port connection more stable and easy to troubleshoot and maintenance.

- Internet + function can remote monitor drilling condition.

- UG\SOLIDWORKS\AUTOCAD software can be used for programming

- Professional and efficient digitized High Frequency system can real time monitor the drilling condition and adjust the HF power to improve the drilling efficiency.

- Intelligent database based on a large number of testing for different machining requirement and can be upgraded for free.

- LED hand remote control box with coordinate display function.

- Basic function of control system

- Operation and input: touch screen, keyboard and mouse.

- 1 absolute coordinate,6 relative coordinates facility for positioning and machining.

- Function of drawing coordination conversion, zoom, rotation, tracing and displaying.

- Auto Short circuit manage function

- Memory function, Auto stop once finishing, stop point setting functions

- Auto edge fining, centering function

- Process path program, interpolation function

- Menu technology, Auto program function

- G code and other files management, Internet date transfer, flash disc reading

- Auto-repair the electrodes.

- Gap servo follow function

- Auto clear Z axis, depth setting function

- Function shift manual or CNC mode machining.

BMD703-500CNC

BMD703-400CNC

- LAN PORT FOR INTERNET FUNCTION

- Real time monitor for operation and modification of parameters.

- Linux operation system, control system build in IC of control module with Libre CAD drawing software. Auto transfer between drawing and points machining by convert software. New program can be prepared during machining.

- Auto edge finding, centering, coordinate setting, original finding, transfer between absolute coordinate and relative coordinate, DXF file reading generated by UG\SOLIDWORKS\AUTOCAD and changing to points machining. G code can be read. Databases function.

Price Terms︰

FOB

Payment Terms︰

TT / LC / DP / DA

Packing︰

PLYWOOD

Lead Time︰

20DAYS

Standards Certificate︰

CE,ISO,PATENTS

Control System︰

ISO9001/ISO14001

Product Image